Rotational moulding

Our rotational moulding step by step

Mixing the LDPE powder

We use LDPE powder (low density polyethylene) as base material for rotational moulding which is dyed in your desired colour.Filling the mould

The ready-made powder is filled into the mould and closed after that.Heating & Rotation

The filled mould now gets heated to 260° C slowly melting the LDPE powder will spread evenly by rotary motion.Final product

After the rotational moulding is completed the cooled down, final product is removed and ready for final assembly.Impressions

By rotational moulding we are able to manufacture all parts forming a hollow body (less weight). Custom requests can be processed as well since the needed moulds are designed and built by us. The finished products are almost stress-free and comparatively immune to pressure or collision. The use of LDPE powder leads to sturdy and chemically resistant product.

Parts we manufacture by rotational moulding are for example toilet fronts, toilet tanks, hand wash stations, urinals and plastic pallets. To gain more insight have a look at our adjacent gallery or just come to see us at our facilities. We are looking forward to your visit.

Vacuum forming

Our vacuum forming step by step

Heating of the sheet

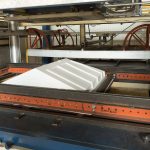

First, we put a sheet of HDPE (high density polyethylene) in desired colour into the thermoforming machine heating it up to 120° C.Formed by vacuum

The now fixed and heated sheet is draped over a mould and stretched to the specific shape using a vacuum.Cool down & remove

The stretched plastic part is cooled down into shape and removed by overpressure.Trimming

In a final step the product is trimmed into its final shape and ready for assembly.Impressions

Vacuum forming is a cost-efficient way to produce large scaled plastic parts out of HDPE (high density polyethylene). Because of HDPE’s great sturdiness and tensile strength parts can be produced with very low wall thickness making it resistant to acids, bases and other chemicals like cleansing agents.

We use vacuum forming for side panels and roofs of our portable toilets as you can see in the adjacent image gallery.

Construction department

Impressions

In the area of vehicle construction, the design and manufacture of fixed-mounted disposal units has been carried out for over 15 years, which are planned and built here according to your vehicle and your specifications.

In 2018, we opened our site in Döbeln and combined our (special) vehicle construction at this production site. Here, the chassis production for the GLOBALINER, the construction of transport trailers in various sizes, of box trailers for various purposes as well as the special vehicle construction for, for example, sales trailers and mask mobiles for film production takes place.